Improved Fluxless Aluminum Brazing Materials and Process Technology for Manufacturing of Advanced Battery Cooling Heat Exchangers

Lead Proponent: Dana Canada Corporation

Location: Oakville, ON

ecoEII Contribution: $ 1,864,069

Project Total: $ 2,662,955

Project Background:

Improvements in thermal modulation of lithium ion batteries is critically needed to improve battery life and operating reliability, and is therefore a key enabler for market adoption of battery and hybrid-electric vehicles. Dana Canada Corporation, a supplier of high-performance compact heat exchangers for passenger-car and light-truck applications, had developed novel battery coolers to manage excess heat generated during battery charging and discharging. Battery systems require exceptionally high levels of cleanliness and freedom from even trace levels of ionic contamination, and preferred configurations require the brazing of extremely thin aluminum panels with high surface areas of internal joints. Dana’s first-generation battery-cooling heat exchanger products were based to a large extent on existing proprietary fluxless aluminum brazing technology previously commercialized for traditional heat-exchanger manufacturing. These battery-cooling products lead the market. However, several challenges were revealed in the manufacturing of these products, including the need to improve the braze system performance on very thin gauge aluminum sheets, environmental efficiencies, and increase manufacturing speeds and cost.

Recognizing the need to address the challenges, Dana Canada proposed the project “Improved Fluxless Aluminium Brazing Materials and Process Technology for Manufacturing of Advanced Battery Cooling Heat Exchanger” for ecoEII funding. The project was awarded $1,269K to improve the constituent technologies involved in fluxless aluminum brazing process for battery cooling applications.

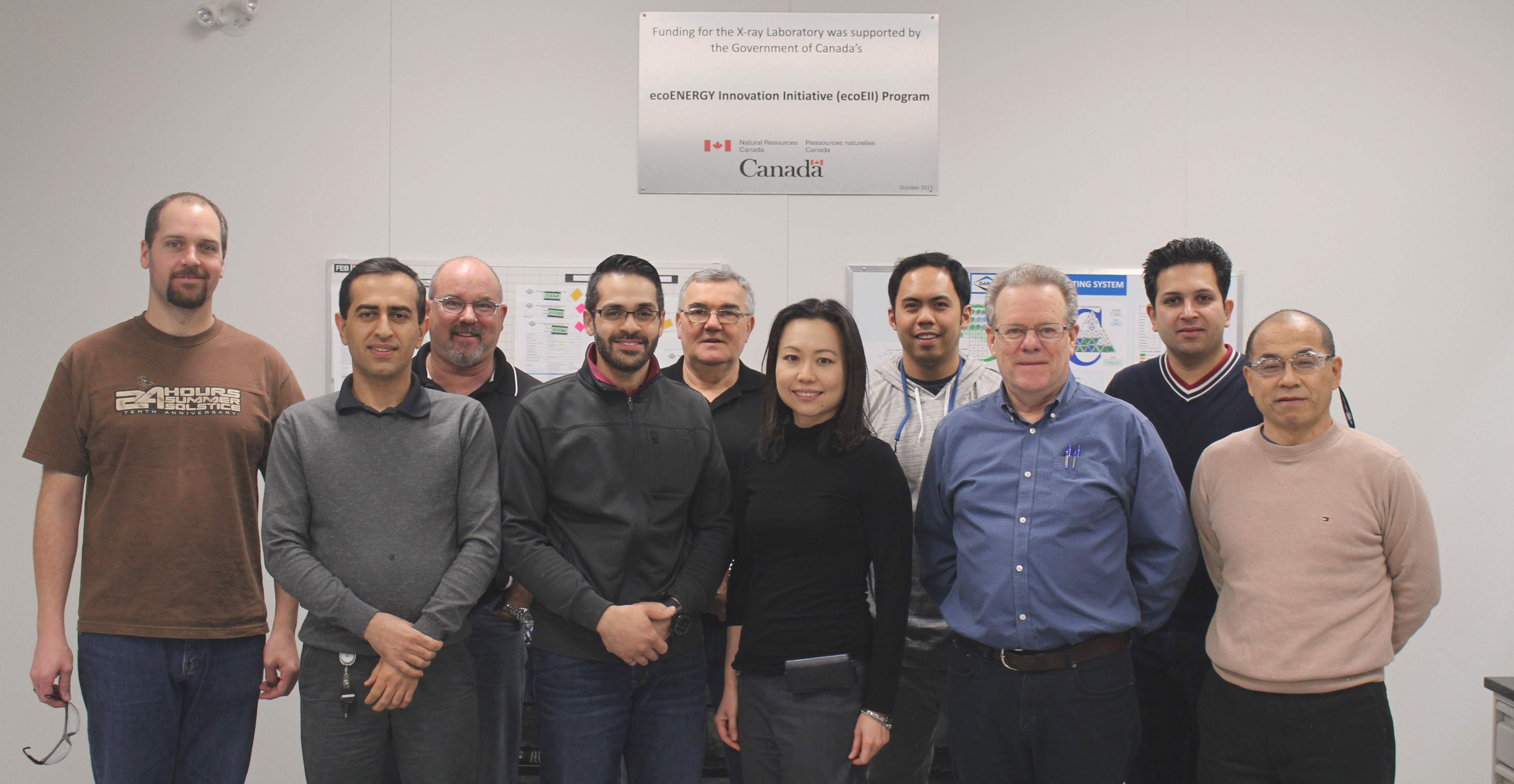

Members of the Dana Canada team. Photo taken in October 2015 in the newly opened X-ray lab at Dana’s Oakville Technical Center, Ontario

Results:

Dana Canada achieved an improved aluminum fluxless brazing process with improved braze performance, environmental and cost efficiencies for the manufacture of next generation of battery cooling products.

In collaboration with the University of Waterloo, ON, and the University of Dalhousie, NS, new material characterization and thermal analysis methods were developed for quantitative studies of various aluminum material systems and manufacturing process sensitivities. This work strengthened Dana’s fundamental understanding of the fluxless brazing process, and allowed for the development of an environmentally friendlier braze promotor formulation and process with improved speeds and braze efficacy.

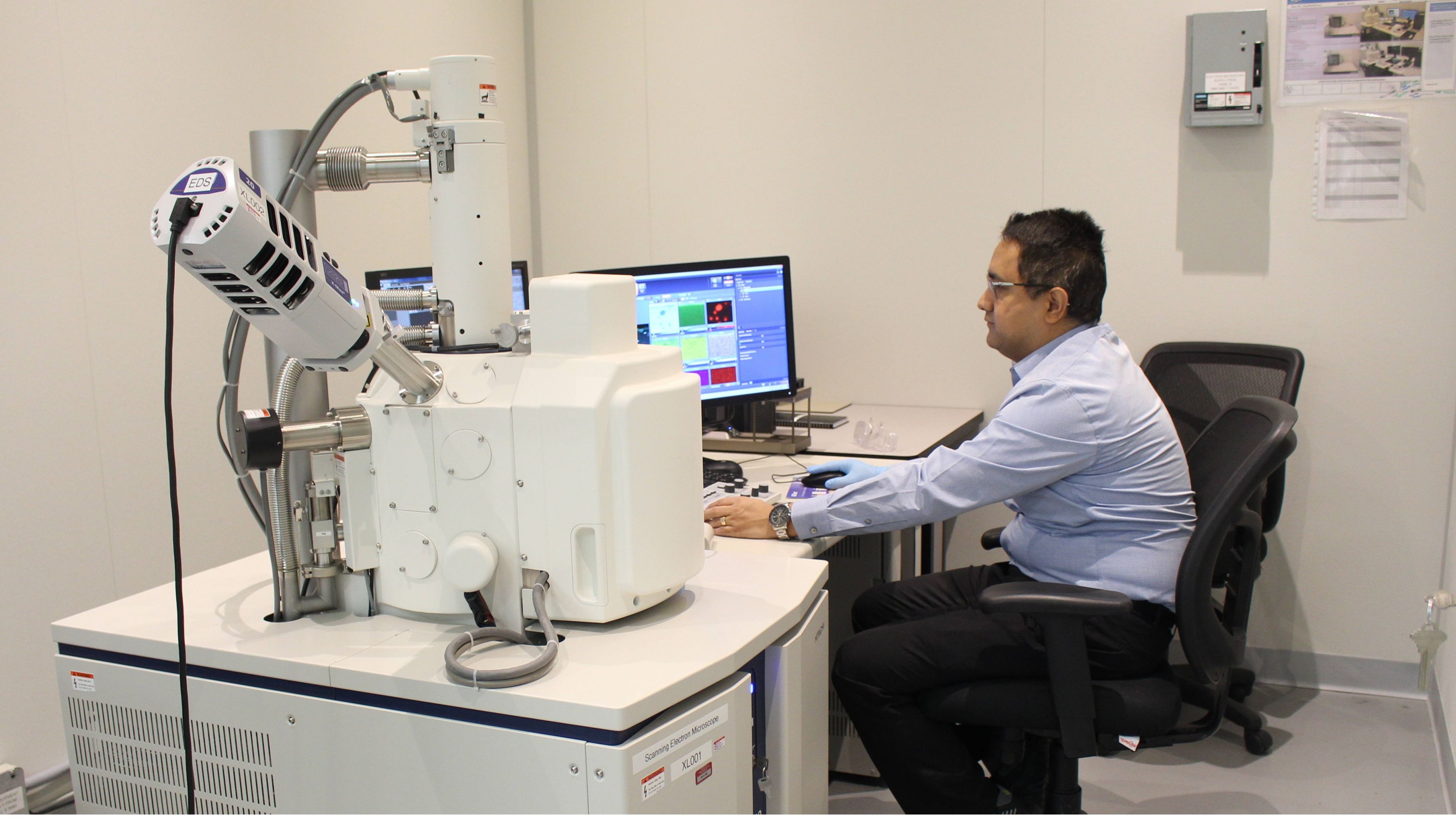

Dana Canada team member performing Scanning Electron Microscopy (SEM) evaluations at Dana’s Oakville Technical Center, Ontario

Utilizing the fundamental knowledge gained, Dana Canada successfully developed, optimized and validated a new fluxless brazing process under pilot production conditions. This included the development of a pilot plating line; pilot process control procedures and specifications; and compliant environmental and health and safety operating procedures. Product level evaluations on different product platforms demonstrated that the performance of the new process to be as good as, or slightly better than, the current production process. Although not part of the project scope, a 50% reduction in production scrap rate was achieved when characterization methods developed during the project was implemented for the manufacture of existing battery cooling products.

Additionally, a new laboratory equipped with a sophisticated computerized 3D Xray Tomography (XRT) and Scanning Electron Microscope (SEM) was established at Dana Canada. These state-of-art advanced characterization tools significantly expanded Dana’s analytical capabilities and competitive advantage for the development of next generation thermal modulation solutions.

Benefits to Canada:

Dana Canada’s efforts will result in an improved manufacturing process with enhanced production yields, environmental and cost efficiencies; for next generation battery thermal modulation systems. This will strengthen Canada’s global leadership in clean technologies, increase the market adoption of electric vehicles, and reduce GHG emissions in Canada.

Next Steps:

Project scale-up to commercialize and deploy the improved technology for the manufacturing of next-generation battery coolers.

Page details

- Date modified: