Medium-density fibreboard

Product description

Medium-density fibreboard (MDF) is an engineered non-structural wood panel made from wood fibres. MDF is typically made up of 82% wood fibre, 9% glue, 8% water, and 1% wax. It is generally used for industrial purposes as a raw material in the production of finished goods, including ready-to-assemble furniture and cabinets.

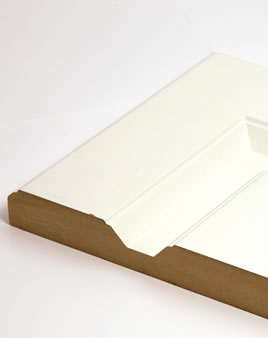

MDF is either hidden from view in a finished product or covered with a decorative coating such as a wood veneer or resin-impregnated paper.

Technical information

MDF is made by breaking down hardwood or softwood residuals into wood fibres. It is combined with wax and a resin binder, and formed into panels by applying high temperatures and pressure. MDF is generally denser than plywood and particleboard. The fibres are produced using a pulping process in which wood chips are treated with steam and broken down by grinding them between ridged steel plates. Mats of wood fibres are then formed by the random distribution of the fibres. This results in a homogeneous panel.

MDF is produced in thicknesses ranging from ¼ inch to 1½ inches. Larger panel sizes can be produced, but panels are typically cut to 4x8 feet sheets for retail purposes. The panels have smooth surfaces suitable for direct painting, printing or laminating.

When cut, MDF produces a tight edge and smooth surface. Therefore, it can be machined and worked like solid wood. The edges can be routed to various shapes and still be smooth enough for a clean paint finish. The small size of the fibres not only make MDF easy to finish, but also allow it to be produced in moulded form as well as in straight-edged flat panels. However, MDF does not hold a screw or nail as well as solid wood, plywood or even particleboard.

Page details

- Date modified: