Combustion Gases in Your Home – Things You Should Know About Combustion Spillage

ARE COMBUSTION GASES SPILLING INTO YOUR HOME?

Does your home have any of these combustion appliances?

- Gas-fired furnace, boiler, or water heater

- Oil-fired furnace, boiler or water heater

- Wood stove or fireplace

- Portable propane, natural gas or kerosene heaters

- Other fuel-burning devices (e.g. gas range)

If so, then heat and combustion gases will be produced as the fuel burns. Normally, these combustion products – which can include both visible smoke and various invisible gases – are vented to the outdoors through a chimney or vent pipe. Unfortunately, in some circumstances, they may instead escape into your home, where they could raise a variety of health and other concerns.

Combustion spillage is a term used to describe the unwanted flow of combustion gases into your home. The quantities involved are usually small; however, each year major or long-term incidences of combustion spillage do occur in some houses, and sometimes with serious or tragic results. You will be provided with some important information about combustion spillage that will alert you to some of the indicators and outline practical steps you can take to reduce the risks. In short, the information found here is designed to educate you of ways to keep combustion gases OUT of your home.

WHY THE CONCERN?

Because toxic compounds can be present in combustion gases, the presence of these gases in household air can lead to problems ranging from nuisance headaches to serious illness, carbon monoxide (CO) poisoning and even death.

Toxic and other harmful substances that can be found in the combustion gases include:

- Carbon monoxide (colourless, odourless and extremely toxic)

- Polycyclic aromatic hydrocarbons

- Aldehydes

- Unburnt hydrocarbons

- Sulphur oxides

- Nitrogen oxides

- Particulates (e.g. soot)

- Carbon dioxide and water vapour - both are present in larger quantities and though relatively harmless can make the indoor environment uncomfortable or contribute to moisture problems in the home

The exact composition and characteristics of combustion gases depends on several factors. These include the type of fuel being burned, the type of burner technology employed, the type of venting system used, and the condition of your heating system. The severity of their effect on your house and occupants is related to these items and also how much fresh air circulates through your house.

UNDERSTANDING VENTING AND SPILLAGE

When Things Go Right

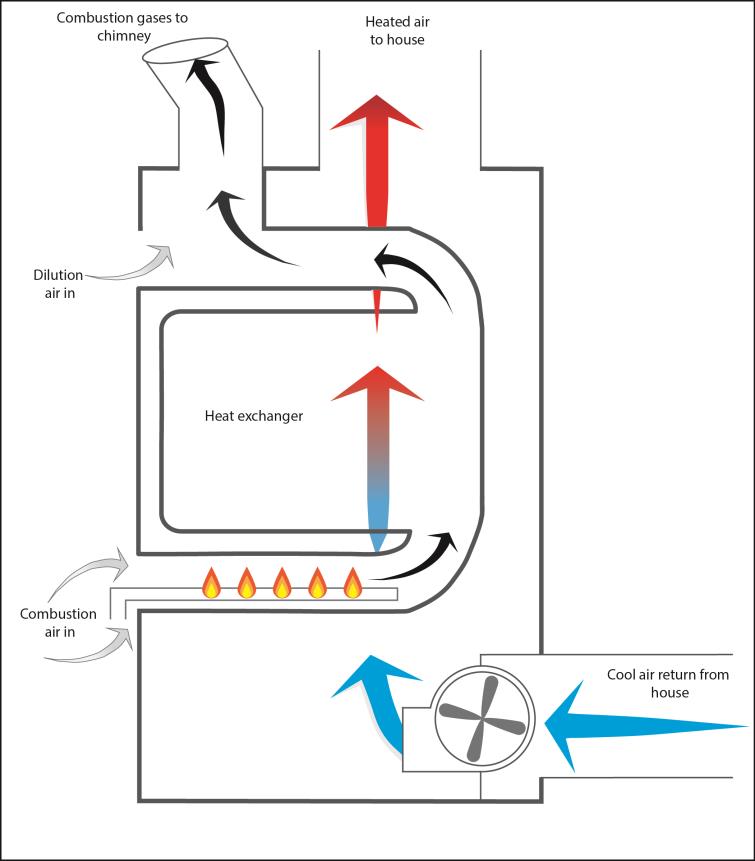

A typical oil or gas forced-air heating system is shown schematically in Figure 1. When operating, the system generates two separate air flows:

1) Combustion air

Depending on the type of heating equipment, the air required for combustion may be drawn into the equipment from the surrounding room, or it may be ducted directly from outside the house. Heating equipment is designed to completely remove the resulting combustion gases from your home.

Figure 1 Basic forced-air heating system airflows

Text Version

Figure 1 - Basic forced-air heating system airflows: Image of a furnace showing blue arrows representing cool air returning from house, flowing upwards through the heat exchanger, becoming heated and supplied back to the house. Combustion air and the circulating air, shown as grey and black arrows, both flow through the furnace as it operates, but never mix with the return and supply air flows.

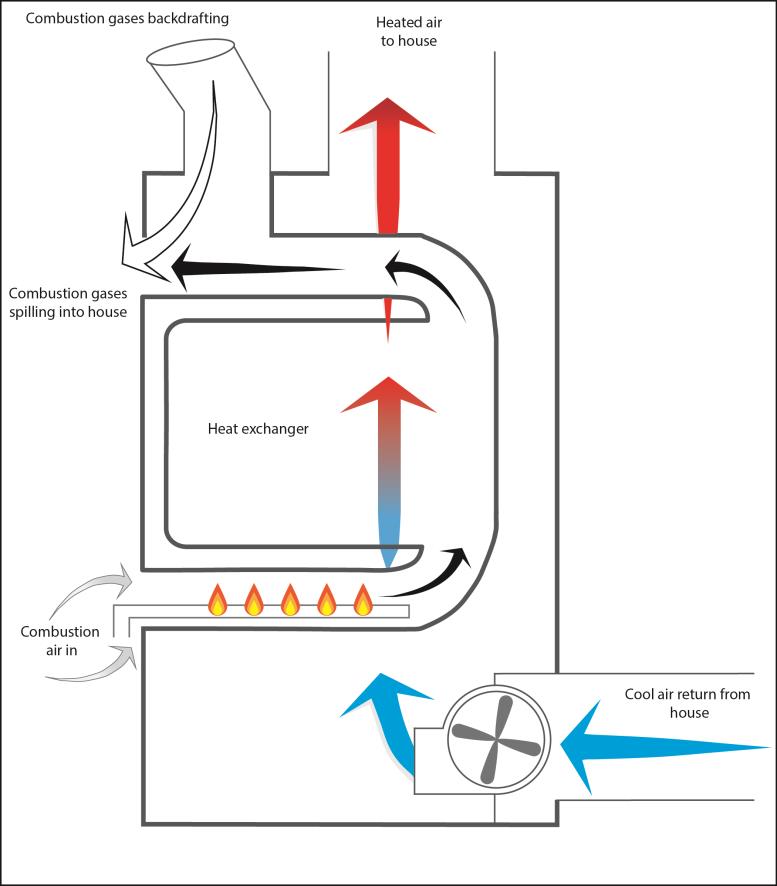

Figure 2 - Combustion spillage from dilution air inlet of a natural draft gas furnace

Text Version

Figure 2 -Combustion spillage from dilution air inlet of a natural draft gas furnace: Image of a furnace shows blue arrows representing cool air returning from house, flowing upwards through the heat exchanger, becoming heated and supplied back air to the house. Combustion air in the house, shown as two grey arrows and then black when passed through the heat exchanger, meets with combustion gases backdrafting from the chimney, represented by a big white arrow, causing combustion gases to spill into the house.

2) Circulation air

The heat generated in the space heating equipment is transferred to the living areas of the home. In a forced-air system, this is accomplished by circulating heated household air. Cooler air is returned to the furnace, heated in a heat exchanger, and returned to the house via the heating ducts. In a properly operating forced-air furnace, the combustion air and the circulating air both flow through the furnace as it operates, but never mix (as shown in Figure 1).

Hydronic heating systems—systems that rely typically on water and radiators to distribute heat—don’t have a circulating air stream. They do, however, require the same supply of combustion air and removal of combustion gases as the forced-air systems.

Similarly, gas- or oil-fired water heaters, fireplaces, and wood stoves all require combustion air, and all require the combustion gases to be vented to the outdoors.

When Things Go Wrong

Unfortunately, combustion systems don’t always work as they should, and combustion spillage can be the result.

Sometimes this spillage is obvious–for instance, if you have a wood stove or fireplace, you may occasionally see smoke escaping into the room. Or if you have a dark stain on the wall above your fireplace, this could indicate combustion product spillage into the room on start-up or during use. In other cases, spillage may not be so evident, in part because the space heating equipment and water heater are usually located away from the main living areas of the home and are relatively clean burning. In addition, many combustion gases, especially from natural gas and propane, are hard to detect because they are invisible and have little or no odour.

Three major factors, working alone or together, can create conditions conducive to combustion spillage in your home. In addition to these factors, unusual winds can also sometimes be at fault.

Factor 1: Chimney / Vent Problems

Your chimney’s job is to remove combustion gases from your home. However, your chimney won’t work properly if it is poorly designed, poorly installed or poorly maintained. There are many causes of inadequate chimney performance or failure. Here are some examples:

- A chimney may be improperly sized—too small for the job or too large to maintain an adequate draft.

- Obstructions such as bird nests, dead animals, broken bricks, collapsed liners and ice can block a chimney’s air flow.

- The incorrect termination (location or height) of a chimney or combustion products vent can put it in a high pressure zone.

- Corrosion may become a problem as a result of condensation or poor construction or installation.

- An uninsulated chimney on an exterior wall is a particular concern because it can become very cold when combustion gases are not present. This can lead to condensation of moisture from the air. When the chimney first fills with moist combustion gases the condensation may increase, at least until the chimney warms up. Condensation can result in damage to the materials in the chimney and ice formation. This in turn leads to problems such as crumbling bricks and ceramic chimney liners, deformed metal liners, cracks and leaks, blockages, and poor draft.

Factor 2: Equipment Problems

Your home’s combustion appliances are made up of several components and, like chimneys, they should be well designed, properly installed, and regularly maintained. Otherwise mechanical problems may prevent combustion gases from venting properly.

As an example, a poorly maintained or damaged furnace or boiler burner may cause incomplete combustion of the fuel resulting in low burner temperatures. This may then cause initial spillage on start-up. Alternatively, a partially blocked or very cold chimney can also promote spillage (see Figure 2).

Factor 3: Pressure Problems

In the winter, we close up our homes. At the same time, we run exhaust fans and numerous other devices that pump air out of the house. In fact, many appliances, particularly fireplaces, exhaust a considerable amount of air even when not operating. As a result, the air pressure indoors falls below the air pressure outdoors and the house becomes depressurized. As the indoor pressure tries to equalize with the outdoors, fresh outdoor air is drawn into the house through openings such as cracks and gaps around windows, doors, and intentional openings in the building structure.

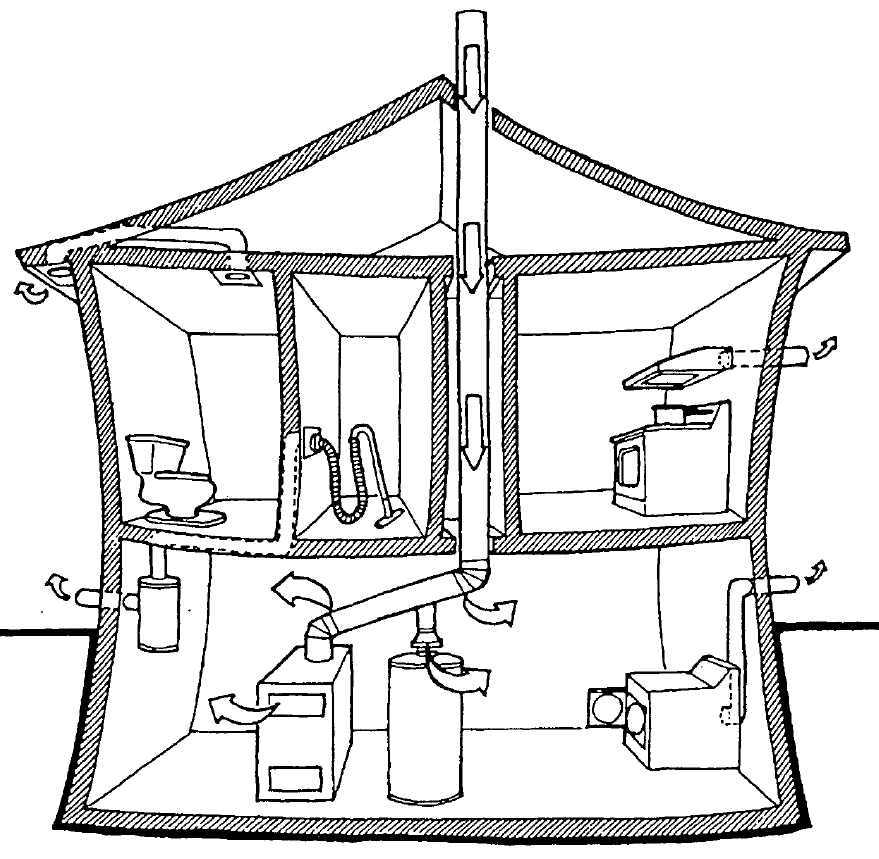

If your house is depressurized too much, air may be sucked back (i.e. the airflow reversed) through the chimney or vent system, especially in natural draft heating equipment. Natural draft equipment utilizes buoyancy to move the heated combustion products up the chimney or vent without the use of fans. When this happens, air flows down the chimney, rather than up—a condition known as backdrafting (see Figure 3). If you have ever opened the fireplace damper before lighting your fireplace and felt the big flow of cold air come into the room, you have encountered backdrafting.

Figure 3 - Backdrafting due to depressurization

Text Version

Figure 3 - House showing backdrafting due to depressurization Image of a two level house with air being exhausted out of the house through bathroom and kitchen exhaust fans, a central vac system and a clothes dryer. The house is shown as if being squeezed as depressurized. Arrows are shown coming down the furnace and hot water tank chimney and represent backdrafted exhaust entering the lower level.

Backdrafting is most common during the “off” cycle of the combustion appliance. If the appliance starts-up while backdrafting is occurring, the downward airflow in the chimney may be difficult to reverse. Combustion product spillage could persist for as long after start-up as it takes for the backdrafting to be reversed. In houses where the “on” cycle is short and the chimney is not insulated or warm, this type of start-up spillage may occur frequently, since the chimney has little opportunity to heat up and establish a good draft. For example, with wood burning the combustion products during start-up are particularly dirty, so even minor spillage of this type should be considered undesirable. In some circumstances, backdrafting can also take place while the combustion appliance is operating– for instance, in a fireplace with a smouldering fire. (See section on What about wood-burning fireplaces?)

PREVENTING COMBUSTION SPILLAGE

As the saying goes, prevention is the best cure. Some of the actions described below will be easier to implement if you are building, renovating or replacing existing equipment. Even if you are not, there is still a great deal you can do.

Maintain Your Combustion Appliances

Start an annual maintenance routine for all your combustion appliances. Get assistance to do this from a qualified professional. The service person should check for heat exchanger leakage, evidence of start-up spillage, and condensation in chimneys.

Maintenance should include a tune-up—a properly tuned combustion appliance rarely produces CO, the most serious threat. If necessary, have your heating equipment adjusted so that it operates on cycles that are six minutes or longer (to minimize start up spillage). Remember that a thorough maintenance check may cost a little more than a simple cleaning, but it is money well spent.

Inspect and Maintain Your Chimney

A blocked chimney will not vent your equipment’s combustion gases. Have a professional check that your chimney is not cracked and is clear of obstacles such as pieces of broken brick, ice or dead animals. This check should be done routinely as part of an annual or bi-annual service call.

Upgrade Your Chimney

Talk to chimney professionals to find out how your chimney’s performance can be improved. If you are building or renovating, try to have the new chimney located on an inside wall to keep it warm.

Have a specialist assess the air supply for your combustion appliances. Remember that even a properly designed combustion air duct will not, on its own, solve spillage or backdrafting problems; chimney and depressurization problems should also be resolved.

Upgrade Your Appliance

When replacing existing equipment or buying new equipment, invest in appliances that are less prone to spillage. Forced draft appliances, which rely on a fan to establish positive venting of combustion gases, are more resistant to spillage. Sealed combustion appliances utilizing direct vent technology isolate the combustion air and combustion gases from the living areas with individual sealed piping that further restricts the possibility of spillage. Ask the salesperson for advice.

Avoid Conditions that Lead to Backdrafting

With a little care, conditions that might lead to backdrafting can be minimized by reducing indoor and outdoor pressure differences.

For instance:

- Be wary of operating several powerful exhaust devices simultaneously such as a high capacity kitchen range hood and a clothes dryer.

- If you install a new range-top with a powerful exhaust fan, get expert advice on how to balance this on the air supply side.

- Avoid combinations of appliances that are likely to create depressurized conditions–for instance, a natural draft furnace with a range-top exhaust fan.

- If your furnace, boiler or water heater is enclosed in a small separate room, allow air to move freely between the mechanical room and the rest of the house. Louvered doors or installed door/wall grills may be the answer.

- If you have a forced-air heating system, be sure you are not drawing return air from the immediate vicinity of your combustion appliances. Also make sure the blower door on your furnace is in place and the air filter opening is sufficiently covered with the air filter frame or is sealed.

WHAT ABOUT WOOD-BURNING FIREPLACES?

Wood-burning fireplaces can be a significant combustion spillage threat and should be treated with great respect. Most people with a fireplace have experienced small puffs of smoke when the fire is lit. They may not know that the smouldering embers of a dying fire can release high concentrations of CO. This happens because when a fire is burning down, little heat is being released; the chimney draft may be very weak and the CO easily spills into the home, sometimes after the occupants have gone to bed.

Fireplace safety measures include chimney maintenance, warning devices and avoiding conditions that are conducive to backdrafting. Extra air from outdoors should always be provided while the fireplace is burning strongly or smouldering. Keeping fireplace doors tightly shut as the fire burns down can also help reduce the potential for spillage. Consider adding tight-fitting doors if there are none or, better still, install an energy-efficient fireplace insert.

BE CAREFUL WITH UNVENTED APPLIANCES

If you have an unvented gas range in your home, be sure to use your outdoor vented range hood, and provide extra ventilation whenever the appliance is operating. Recirculating range hoods do not remove combustion products. Never use an unvented natural gas cooking appliance as a space heating device – there is a real potential for CO poisoning.

Unvented portable space heaters should not be used indoors. Never use a charcoal or gas barbeque indoors.

DETECTING COMBUSTION SPILLAGE PROBLEMS

Even with a good prevention program, you should be on the look-out for combustion gas spillage.

Watch for warning signs such as:

- Repeated headaches, skin and throat irritations, shortness of breath or impaired motor function

- Combustion odours anywhere in the house

- Hot and muggy air around the heating equipment

- Soot stains around any combustion appliance, ductwork, registers, or unusual rumbling sounds when it is operating

- Melted plastic fittings at top of domestic water heater

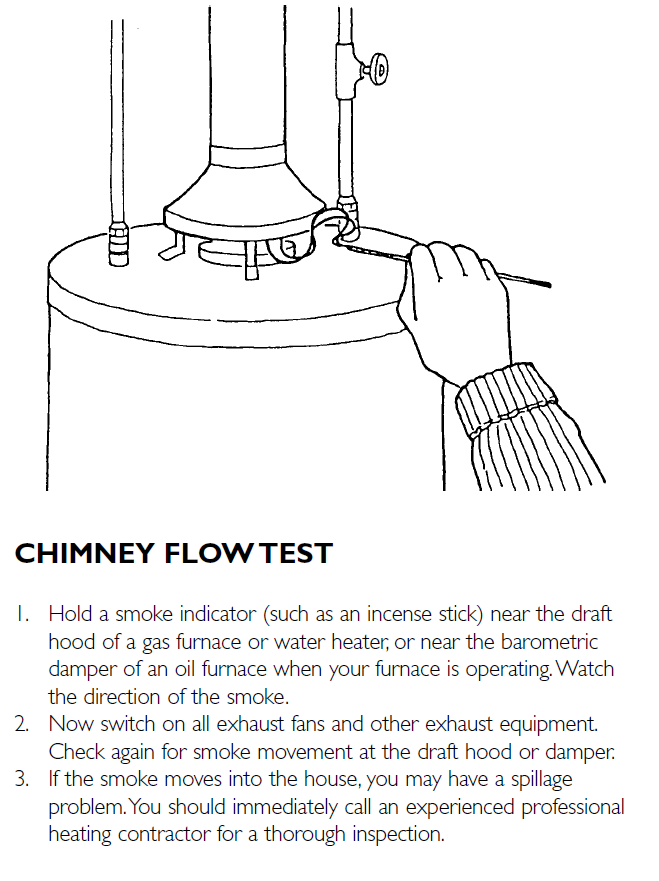

Do the Chimney Flow Test, a quick and simple procedure that will give you an indication of how well your chimney is working as shown in Figure 4 – please note: this test is not possible for sealed combustion appliances.

Install warning devices. Smoke and CO alarms should be used whenever combustion appliances are present. Buy a CO alarm certified to the current Canadian Standards Association (CSA) 6.19 Residential Carbon Monoxide Alarming Devices Standard. Smoke and CO alarms should be installed according to the manufactures installation instruction and local building codes. Your local fire department or building official may be able to make recommendations about installations.

Be aware that CO poisoning can occur if exposed to a large amount of CO over a short period of time or by a small amount of CO over a long period of time especially if a person’s body has limited ability to use oxygen (e.g. people suffering from asthma and other respiratory problems). Locating a CO detector close to or audible from bedrooms is also a good idea. However, be aware that CO alarms may not be triggered by some situations such as long term, low-level exposures. Also, though not related to combustion spillage, an idling vehicle in an attached garage may trigger a home CO alarm when exhaust fumes migrate through leaky common walls, doors and ceilings. Avoid idling a vehicle in a garage.

Note that all smoke alarms and detectors have expiry dates and should be replaced as per manufacturer’s instructions. In addition, for battery powered units or those with electric units with battery back-up, change the batteries annually or as per manufacturer’s instructions. CO alarms should also bear the CSA logo.

Figure 4 - Chimney Flow Test

- Hold a smoke indicator (such as an incense stick) near the draft hood of a gas furnace or water heater or near the barometric damper of an oil furnace when your furnace is operating. Watch the direction of the smoke.

- Now switch on all exhaust fans and other exhaust equipment. Check again for smoke movement at the draft hood or damper.

- If the smoke moves into the house, you may have a spillage problem. You should immediately call an experienced professional heating contractor for a thorough inspection.

Text Version

Figure 4 - Chimney Flow Test Hand holding a stick of incense near the draft hood of a gas furnace

CORRECTING COMBUSTION SPILLAGE PROBLEMS

If you have a combustion spillage problem, it is important to deal with it promptly. Often, solutions to existing problems and prevention of future problems require similar strategies. Once you have determined that you have a problem or have identified a cause, consider the relevant actions described under Preventing Combustion Spillage. Ensure that all necessary repairs or improvements are done as quickly as possible, and by experienced professionals. If you are unsure about your options, consult the web or your telephone directory to find professionals who specialize in, for example, ducting, building inspection, indoor air quality, chimneys, and heating equipment. Your fuel supply company may also be able to provide assistance.

Although this information product reflects housing experts’ current knowledge, it is provided for general information purposes only. Any reliance or action taken based on the information, materials and techniques described are the responsibility of the user. Readers are advised to consult appropriate professional resources to determine what is safe and suitable in their particular case. Natural Resources Canada assumes no responsibility for any consequence arising from use of the information, materials and techniques described.

Page details

- Date modified: