Walk-in refrigeration

Regulations set the energy efficiency minimum

Walk-in freezer and walk-in cooler components are subject to Canada's Energy Efficiency Regulations, which set a minimum performance standard for their energy efficiency. Find details in the Guide to the Regulations.

How a typical system works

Walk-in refrigerators and freezers are very large, insulated, enclosed spaces used to store and/or display refrigerated or frozen food or other perishable goods. They are used primarily in the food service and food sales industry. Where commercial refrigerators and freezers used in supermarkets and food processing and packaging can be much larger and are typically supplied by central refrigeration systems.

Walk-in refrigerators operate above 0°C and at or below 13°C, and walk-in freezers operate at or below 0°C. The room is cooled by a packed unitary or split refrigeration system consisting of:

- an evaporator fan coil (usually mounted on the room’s ceiling)

- a compressor (usually mounted outside the room)

- a water- or air-cooled condensing coil

Refrigerant continuously circulates from the compressor to the condenser, into the expansion device, through the evaporator and back to the compressor.

The refrigerant absorbs heat from the room and expels that heat through evaporation and condensation within the closed refrigeration system. The heat may be expelled into the building, outdoors, or into cooling water.

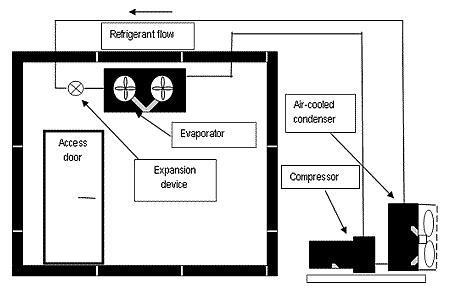

Diagram of a typical walk-in refrigerator or freezer

Text version

A Typical Walk-In Refrigerator or Freezer A cross section of a typical commercial walk-in refrigeration or freezer. Located on the ceiling of the room, are the evaporator and the expansion device. The air-cooled condenser and the compressor are located outside the room. The refrigerant continuously circulates from the compressor to the air-cooled condenser into the expansion device and through the evaporator and then back to the compressor.

Know what you need

To choose the most efficient refrigerator or freezer, consider:

- the temperature the unit must maintain

- the functions the unit must perform (refrigeration, freezing or both)

- the configuration of doors required for access and/or display

- the speed at which cooling or freezing must occur (for health reasons)

Opting for increased efficiency

There are many options that reduce energy transfer and, therefore, energy use:

Insulation

- better insulation in walls, ceiling and floor

- better gaskets and sealing materials for doors

- improved materials, geometries, and manufacturing techniques in panel interface systems for better overall insulating capacity of the envelope

Lighting

- high efficiency lighting (LEDs) and electronic lighting ballasts

- fiber optic lighting gathered from rooftop collectors

- occupancy sensors turn inside lights on only when a person is present

In-and-out

- vestibule entryways and revolving doors

- automatic door opening and closing systems

- air curtains, especially recirculating models, and even strip curtains

- automatic evaporator fan shut-off whenever the walk-in door is opened

Controls and monitors

- refrigeration system override for off-peak hours

- air and water infiltration sensors to monitor condition of insulation

- evaporator fan control to run at variable speed, or cycle on and off, during periods when the compressor is off

Efficient technologies

- higher efficiency compressors

- higher efficiency evaporator and condenser fan blades

- improved evaporator and condenser coils

- higher efficiency fan motors, e.g. three-phase, ECMs and PSCs

For an overview of high efficiency food services equipment see our ENERGY STAR Guide for Commercial Kitchens [PDF - 2.1 MB].

Find out more information on our Buying tips and operating tips page.

Page details

- Date modified: