Waste Heat Recovery and Upgrading

Every year, significant amounts of energy produced by industrial processes are wasted in the form of liquid or gas flows. From an industrial point of view, energy recovery from waste heat is a priority and provides the best opportunity for reducing energy consumption.

Identifying sources of waste heat in a given facility is relatively easy. However, determining the most appropriate applications and technologies for recovering such heat requires a great deal of perseverance and creativity. The possible applications are numerous and wide-ranging as they vary from one industrial sector to the other, and even from one location to the next within a given industrial process.

Decision-Support Tool

This project’s main objective is to develop a decision-support tool for use in determining the best solutions for waste heat recovery and upgrading, while taking into account the following:

- A plant’s overall context (i.e. determining how any given waste heat flow can best be used considering the plant’s other energy flows)

- Impacts on energy generation services in order to assess real savings rather than apparent savings observed in a given plant sector

- Possible improvements to existing energy generation services, including refrigeration, steam generation and distribution, and power generation systems

Database, Classification and Methodology

The project will also result in:

- An electronic database containing detailed information on a wide range of waste heat recovery and upgrading technologies, including performance models

- The classification of waste heat sources and identification of typical projects providing energy savings in various industrial facilities

- The development of a methodology for better knowledge-based decision making and of energy generation service models

CanmetENERGY is seeking partners interested in collaborating on this research project. To discuss a potential partnership, please contact us.

Text Version

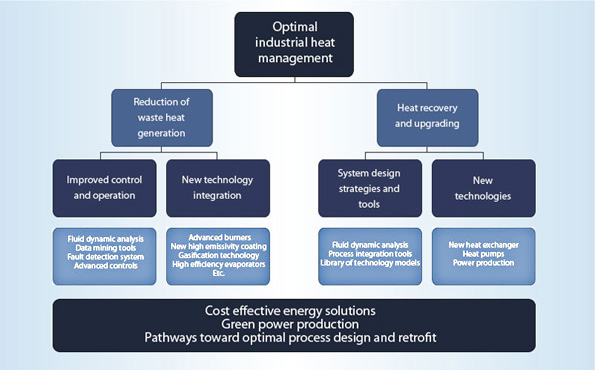

Text version of images - Waste heat pathways

Waste heat pathways

Optimal industrial heat management translates into:

- Reduction of waste heat generation

- Heat recovery and upgrading

Reduction of waste heat generation includes:

- Improved control and operation

- New technology integration

- Fluid dynamic analysis, data mining tools, fault detection systems, and advanced controls

- Advanced burners, new high emissivity coating, gasification technology; high efficiency evaporation, etc.

Heat recovery and upgrading includes:

- System design strategies and tools

- New technologies

- Fluid dynamic analysis, process integration tools and library of technology models

- New heat exchanger, heat pumps and power production

All these technologies and tools provide:

- Cost effective energy solutions

- Green power production

- Pathways toward optimal process design and retrofit

Page details

- Date modified: