Froth Treatment

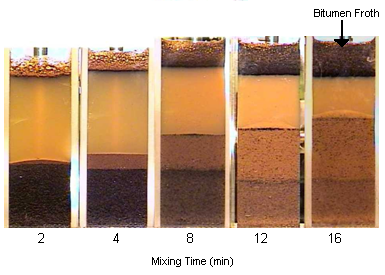

Formation of bitumen froth

Froth treatment is the process of eliminating the aqueous and solid contaminants from the froth to produce a clean bitumen product. The froth is first diluted with a hydrocarbon solvent to reduce the viscosity and density of the oil phase, thereby accelerating the settling of the dispersed phase impurities by gravity or centrifugation.

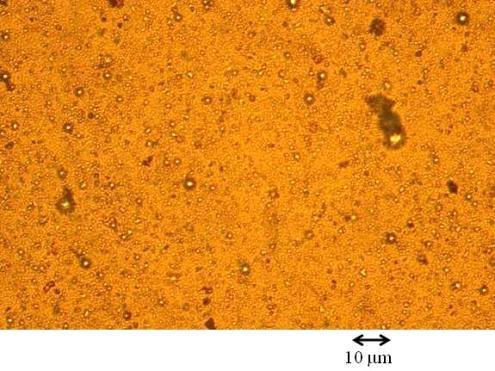

The bitumen product is called "diluted bitumen." The solvent is recovered from the diluted bitumen to be used again. The challenge is to remove emulsified water and colloidal mineral particles as shown in the microscopic image below.

There are two major technologies used for froth treatment. In conventional froth treatment, the solvent naphtha is used at relatively low solvent-to-bitumen ratio. The separation is enhanced by addition of chemicals to destabilize the emulsion. Typical diluted bitumen products from this process contain 1-2% percent of water and about 0.5% mineral solids. Because of the level of contamination, the bitumen is not suitable for pipelining or refining. The bitumen is therefore upgraded using heat to produce synthetic crude oil by means of a coker unit.

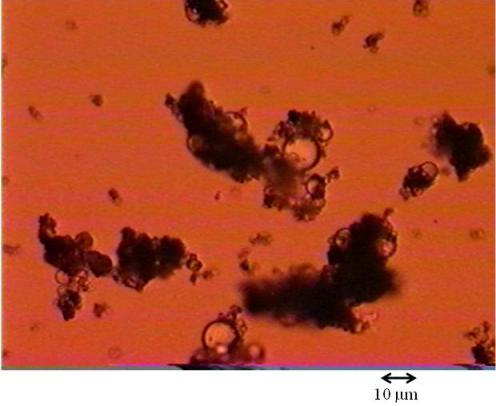

Typical microscopic view of emulsified water in diluted bitumen

The second technology is Paraffinic Solvent Froth Treatment (PSFT), which is a relatively new method of bitumen froth treatment. This treatment was developed in 1990 with significant research contribution from CanmetENERGY. The bitumen product obtained through PSFT has lower levels of contaminates, such as water and mineral solids, reaching almost 2 orders of magnitude. The content of asphaltenes, which are heavier molecules contributing to the high viscosity in the bitumen, can also be lowered, thus upgrading the bitumen quality. Mixing paraffinic solvent at required solvent-to-bitumen ratio (S/B) results in the formation of aggregates composed of emulsified water droplets, mineral solid particles and precipitated asphaltenes shown in the microscopic image below. Aggregated contaminants are easy to separate in conventional settlers, requiring less energy.

Microscopic view of aggregated droplets of emulsified water and mineral solids in paraffinic froth treatment

Managed by CanmetENERGY at the Devon (Alberta) research centre.

Page details

- Date modified: