Innovative Biomass Supply Chain Solutions for Commercial and Institutional Heating Plants Used in the Forestry Sector

Lead Proponent: Quebec Federation of Forestry Cooperatives

Location: Ste-Foy, Quebec

ecoEII Contribution: $ 604,000

Project Total: $ 1,004,000

Project Background

Forest biomass from sustainably managed forests refers to trees or parts of trees unused by traditional wood processing industries; this biomass consists of total and partial harvesting residues (branches and crowns), unused species, low quality trees, and stands affected by natural disturbances (fires and insects). This forest biomass represents the largest source of raw material currently available for bioenergy production in Canada, but its potential has gone largely untapped due to the many logistical, economic and environmental barriers associated with its deployment, as well as significant knowledge gaps. It is essential to develop new and innovative approaches to forest biomass supply chain organization for bioenergy production in order for Canada to develop this sector to its full potential. To that end, the Quebec Federation of Forestry Cooperatives (FQCF) proposed a project “Innovative Biomass Supply Chain Solutions for Commercial and Institutional Heating Plants Used in the Forestry Sector” for ecoEII funding. The Project was awarded $604K to develop, improve and optimize sustainable forest bioenergy systems that are cost-effective and efficient in terms of mitigating greenhouse gas (GHG) emissions in forest communities. FQCF brings together and represents the common interests of cooperatives in Quebec’s forestry sector. Its mission is to implement a framework for cooperative development to provide, ensure and create stable and meaningful employment for members of the forestry cooperative network, and to help maintain and develop Quebec’s forestry cooperative network and businesses.

Results

Text Version

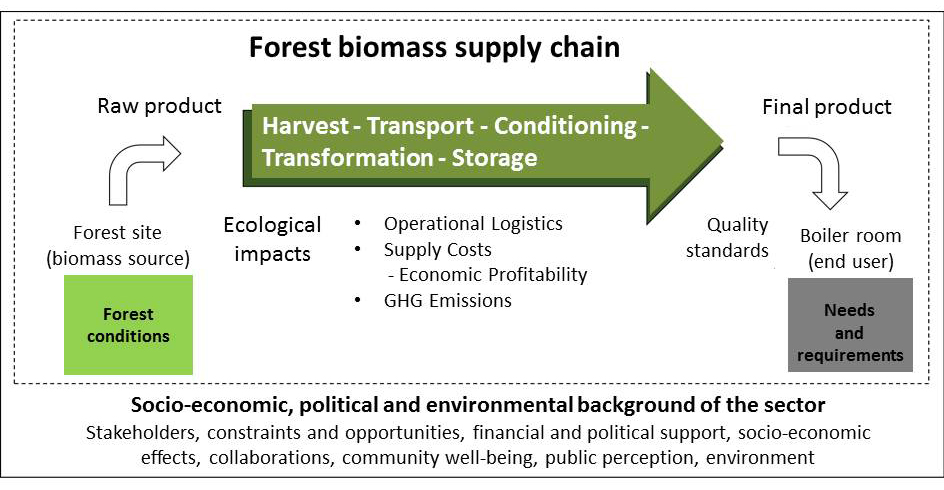

On the one hand, we have a resource - forest biomass - and on the other, a client and boiler room requiring a fuel (biomass in wood-chip form) that meets the boiler manufacturer’s requirements. The project made it possible to document impacts on the forest environment and to suggest some guidelines for minimizing these impacts. It also made it possible to document all of the processes and steps involved in the fuel’s production, from woodland harvesting right up to delivery to the boiler, by way of raw biomass transport, storage for conditioning, transformation to achieve the required particle-size distribution characteristics, and re-storage under shelter with the evaluation of different biomass drying techniques to achieve the desired moisture content. The evaluated forest biomass supply chain therefore comprises all of these steps, through which issues of operational logistics, supply costs and economic profitability were addressed. For a number of sample projects, the concrete bioenergy project’s carbon footprint for this entire chain was calculated, which made it possible to calculate the GHG emission reduction compared with the reference scenario if bioenergy had not been used. Finally, all of the bioenergy production activities have an impact on the socioeconomic environment. These impacts were also documented, as were political support for the sphere and the public perception of development of the heat production sector.

The Project was carried out from April 1, 2013 to March 31, 2016. During those three years, a number of operational, environmental and socio-economic studies were led by the proponent and the various participating partners. More specifically, the Project involved 20 partners from academia, research centres, the forestry cooperative network and various private sector companies specializing in bioenergy. The Project looked at three main issues with regards to residual forest biomass supply chains for heat production: operations (logistics and profitability of the supply chain from the harvesting site until delivery of the final product; forest biomass conditioning and storage strategies); environment (environmental issues relating to the harvesting of forest biomass); and, socio-economics (community players’ characteristics and socio-economic effects).

The Project was organized in three phases. In Phase 1, literature reviews were conducted on forest biomass supply chain models in Canada and in the world, as well as on ecological issues associated with the harvesting of forest biomass in Canada’s boreal forest. In addition, an exploratory study was conducted to help identify stakeholders in the supply chain and to evaluate the socio-economic effects of the forest biomass sector. Phase 2 involved field testing in order to validate, adapt and close the gaps identified in Phase 1, including testing of harvesting of forest biomass during a clearing operation in degraded hardwood stands, as well as in commercial thinning of a softwood forest stand. Six drying tests were carried out to provide answers with regards to forest biomass drying strategies in the form of chips. Two forest biomass transformation tests were carried out with different machinery configurations. Phase 3 wrapped up the project with analysis of results, and transfer and dissemination of knowledge. The solutions identified throughout the Project correspond to all stages of the residual forest biomass supply chain, from the logging site to delivery of the final product. Mastering each of these stages, as well as the logistics and coordination of each step is essential to obtaining a quality product that meets the needs of commercial and institutional boiler rooms. Furthermore, ecological and socio-economic issues must also be considered.

Benefits to Canada

The development and validation of quality standards and practices for forest biomass specific to Quebec and Canada represented a major step from an innovation point of view and resulted in decisive steps for sector deployment. Forestry cooperatives in Canada are better able to recover biomass, replace fuel oil or propane and reduce GHG emissions.

Next Steps

Service Forêt-Énergie, a subsidiary of the FQCF, will ensure that the Project’s results and knowledge products are adopted by its members. Data sheets, a series of articles in the journal Le Monde Forestier, and a training event are planned throughout 2016. The Project could lead to a subsequent stage of R&D, to other field tests, as well as tests at an operational scale.

- Clearing and recovery of BIOMASS (Available in French only)

Please contact the ecoENERGY program to obtain a copy of the FQCF Final Public Report.

Page details

- Date modified: