Integrated Approach to Development of a High Efficiency Energy Recovery and Intelligent Ventilation System

Lead Proponent: dPoint Technologies

Location: Vancouver, BC

ecoEII Contribution: $ 704,000

Project Total: $ 939,000

Project Background:

Current Energy Recovery Ventilator (ERV) exchangers are limited in their energy recovery efficiency by the exchanger design and the water vapour permeability of membrane materials. This presents a need for exchangers with higher total energy recovery. In North America, cross-flow ERV cores are typical, but their transfer mechanism limits the heat transfer rate relative to flow rate. To obtain higher sensible heat transfer, which is important for reducing heating loads in the winter, a counter-flow core is a more efficient design. Furthermore, current ventilation and energy recovery systems lack the ability to operate optimally from an energy efficiency standpoint while ensuring adequate indoor air quality (IAQ). Ventilation control strategies should be based on inputs such as indoor and outdoor climate conditions, IAQ, the cost of electricity, and the comfort of the building occupant. To evaluate ventilation control strategies which minimize energy utilization while maintaining acceptable levels of comfort and air quality within buildings, an integrated approach is required. The energy recovery exchanger (core), the energy recovery ventilator system, the heating, ventilation and air conditioning system (HVAC) controller, and the building HVAC system should all function optimally together. Recognizing the need to improve energy consumption and indoor air quality in buildings using an integrated approach, dPoint Technologies proposed the project "Integrated Approach to Development of a High Efficiency Energy Recovery and Intelligent Ventilation System" for ecoEII funding. The project was awarded $704K.

Results

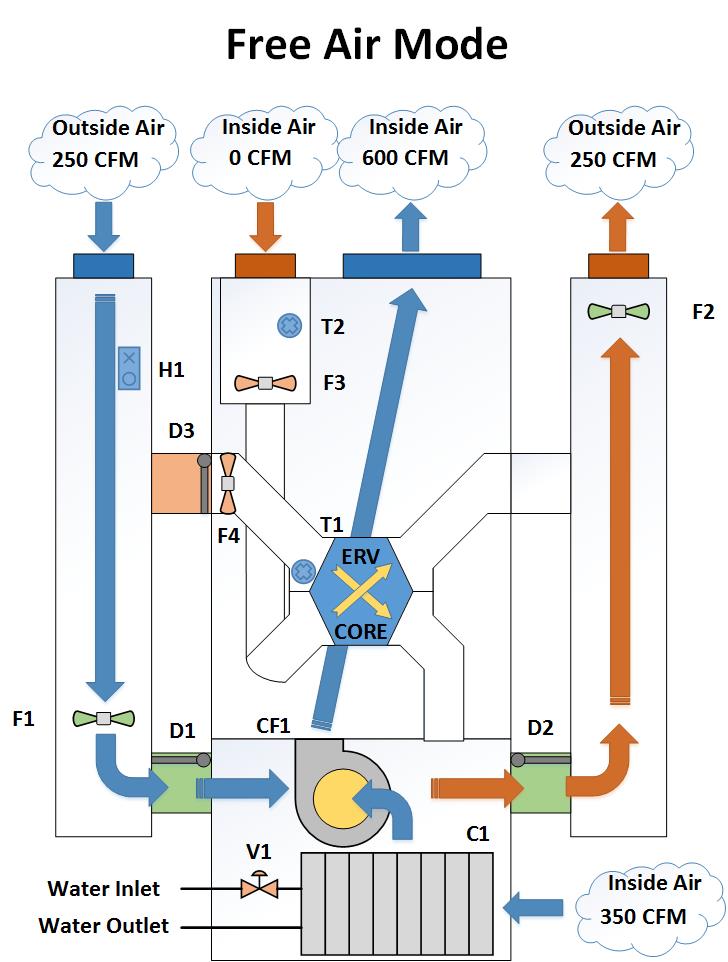

Diagram showing ERV operating in Free Air Cooling Mode

Text version

In Free Air Cooling Mode, valve V1 is left shut and no water enters the coil C1. The centrifugal fan CF1 then begins operating at an increased speed while fans F1 and F2 are turned on. Dampers D1 and D2 are opened to allow outdoor air to enter and exit. Hygrometer H1 is used to analyze the temperature (and optionally humidity) of the incoming outside air. When the set-point of the thermostat is reached, Free Air Cooling Mode is suspended and the system returns to the standard Run Mode. Fans F3 and F4 remain off while damper D3 remains closed during this operation. It is still possible to trigger ERV HIGH SPEED MODE during this operation but the ERV will ignore this input until the Free Air Cooling Mode is complete. Through this operation, the unit can bring in the right amount of cold outside air (on a sunny spring/fall day) to lower the temperature of indoor air instead of using the cooling coil.

A prototype counter-flow ERV core was designed and constructed. It consisted of a self-supporting corrugated structure made solely out of membrane and manifolding to alternating cells. The core design incorporated two dimensional heat and latent heat transfer concepts. Performance of the prototype core was validated by an independent lab to have over 80% sensible effectiveness (related to transfer units for heat) for both heating and cooling conditions. Total (enthalpy) effectiveness was calculated to be over 60% in cooling conditions, at a comparable pressure drop to other exchangers.

The high-performing ERV core was then incorporated into the design of a prototype fan-coil system. Enerzone, dPoint’s project partner, designed and built the custom integrated fan-coil (IFC) system, incorporating smart controls to take advantage of “free cooling” when in economizer mode. The IFC system would mix in cold fresh outside air to perform cooling instead of relying on an additional active cooling system. Its control algorithm was designed to take advantage of the free cooling effects of colder outside air, such as during the shoulder seasons (spring/autumn) when solar irradiation increases the indoor air temperature to a point where cooling is necessary. A hygrometer placed on the inside of the air intake measures the temperature and humidity of the incoming outdoor air.

The IFC system incorporating the ERV core and controls was subsequently installed and commissioned in a condominium building in Toronto. A benchmark standard heat recovery ventilator system was installed in one suite (vacant but fully equipped) and the integrated ERV system was installed in another – one suite on top of the other. dPoint partnered with Tower Labs to verify the performance of the integrated ERV in real world conditions. Equipment and sensors were installed to collect data and monitor the systems over the shoulder (spring) season. Data was analyzed and results indicated that when temperatures escalated and free cooling was available, the integrated ERV system reduced the active cooling requirement by a measurable amount (when economizer mode was active). The system was able to cool the living space by up to 2°C with free cooling, as compared to the suite without the integrated ERV. According to a report published by RDH Building Science Consulting, it is likely that 12% of the hours that would require cooling in Toronto would be appropriate for free cooling, resulting in a reduction of a building’s overall external cooling load.

Benefits to Canada

Canada’s extreme climate with cold, dry winters and hot, humid summers drives large energy consumption for building heating, cooling, ventilation, humidification and dehumidification. A high efficiency energy recovery system would reduce electricity use, natural gas consumption and greenhouse gas emissions in all types of buildings in Canada.

Next Steps

The newly developed integrated IFC ERV system would benefit from extensive in-field monitoring and verification testing over longer periods of time (with the system in economizer mode). Design of the unit could also be improved so that the system fits into utility closets.

Page details

- Date modified: