Development of Thick Film Electric Heaters for Thermal Modulation of Battery Systems

Lead Proponent: Dana Canada Corporation

Location: Oakville, ON

ecoEII Contribution: $ 1,192,765

Project Total: $ 1,666,000

Project Background:

Lithium-ion batteries used in battery and hybrid electric vehicles must operate in a narrow temperature range to maintain efficiency, durability and reliability. In order to achieve temperature control, novel battery coolers were developed by Dana Canada Corporation to manage excess heat generated during battery charging and discharging. However, battery function and durability is also significantly compromised in cold climate conditions such as those encountered during Canadian winters. Accordingly, there is a need for improved battery cooling heat exchangers that can also function as heaters, to improve battery system performance when operating at cold temperatures. A preferred solution involves a sol gel thick film heater technology applied directly to the surfaces of heat exchangers. However, significant technological gaps exist to adapt and integrate this technology into automotive systems for improved performance, durability, and cost.

Recognizing the need to address the technological gaps, Dana Canada Corporation proposed the project “Development of Thick Film Electric Heaters for Thermal Modulation of Battery Systems” for ecoEII funding. The project was awarded $843K to develop and integrate sol gel thick film heaters directly onto battery cooling heat exchangers.

Results:

Participants of the Dana-Datec partnership who met at Dana’s Oakville Technical Center in Ontario for a project progress meeting.

Dana Canada collaborated with Datec Coatings Corporation, a leader of composite sol gel thick film heaters, to adapt and optimize the heater laminates for design and manufacturing integration into Dana’s heat exchangers for thermal modulation of automotive high-voltage battery systems.

An improved heater material system with superior performance and durability, and a cost-effective heater film manufacturing process, was developed. Adhesion and life cycle testing were carried out to select the optimal heater materials and co-firing studies of the laminate layers on aluminum heat exchangers were conducted to optimize the manufacturing process parameters and reduce the number of firing stages. Additionally, in order to incorporate the battery thermal modulation devices into the vehicle powertrain, a compatible low-cost and durable connector design was developed.

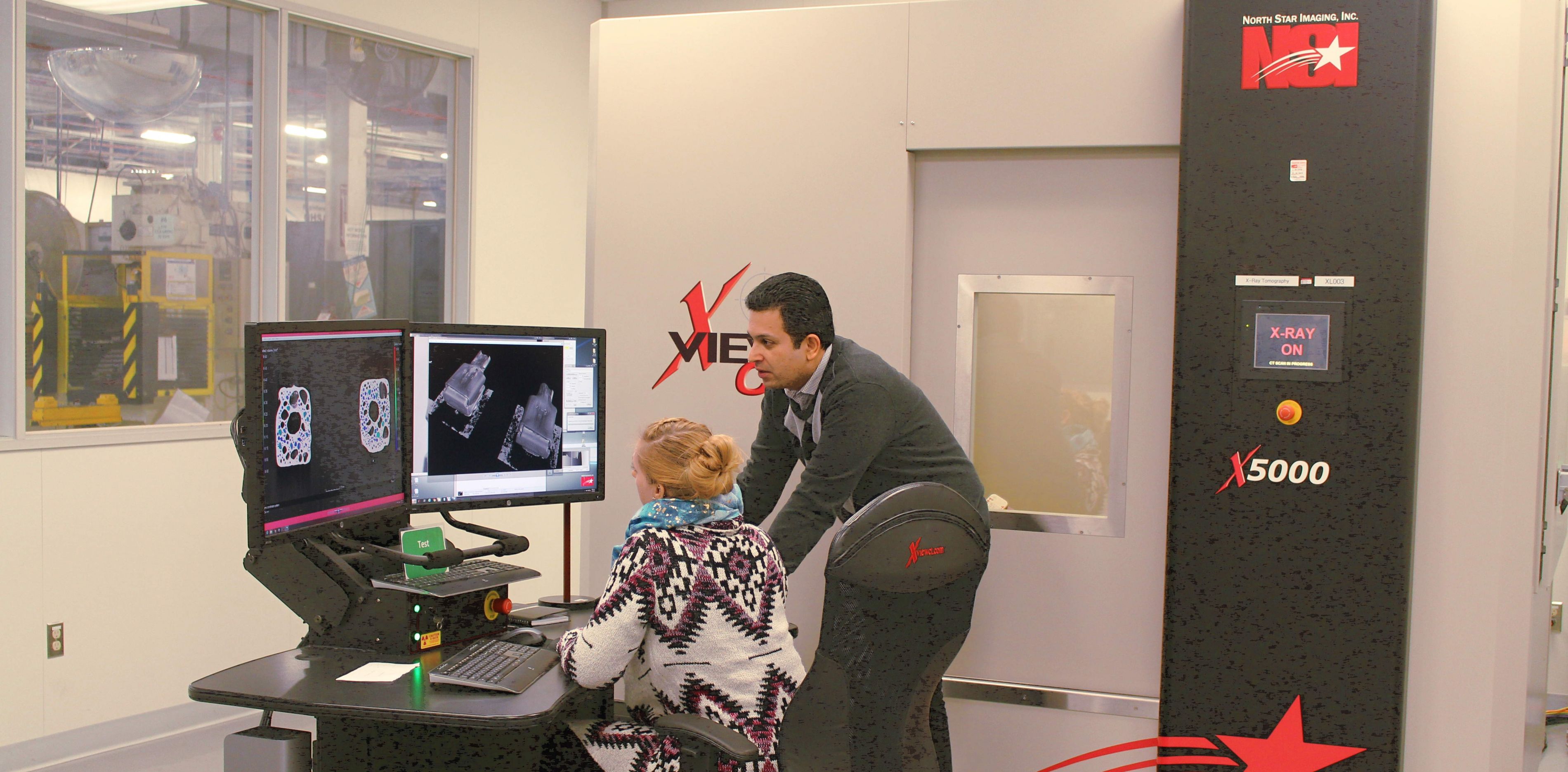

Members of the Dana Canada team performing 3D X-ray Tomography (XRT) evaluations on an early prototype at Dana’s Oakville Technical Center, Ontario.

The Dana and Datec partnership lead to design and development of customer demonstration prototypes that successfully integrates the sol-gel heater technology onto automotive aluminum heat exchangers for battery system application. Customer demonstration prototypes tested at potential customer sites passed long-term life cycle durability testing and exceeded performance expectations.

Additionally, a new laboratory equipped with a sophisticated computerized 3D Xray Tomography (XRT) and Scanning Electron Microscope (SEM) was established at Dana Canada. These state-of-art advanced characterization tools significantly expanded Dana’s analytical capabilities and competitive advantage for the development of next generation thermal modulation solutions.

Benefits to Canada:

Dana Canada’s efforts will result in new low-cost energy efficient battery thermal modulation systems that will improve the performance and life of next generation battery and electric vehicles. This will strengthen Canada’s global leadership in clean technologies, increase the market uptake and production of electric vehicles, and result in reduced GHG emissions.

Next Steps:

Continue the next phase of development with potential customers to commercialize the technology for next generation battery and electric vehicle applications.

Page details

- Date modified: